PCBA Capabilities

We are professional on PCB and turnkey PCBA solution, owing to the past over 15 years rich experience of manufacturing

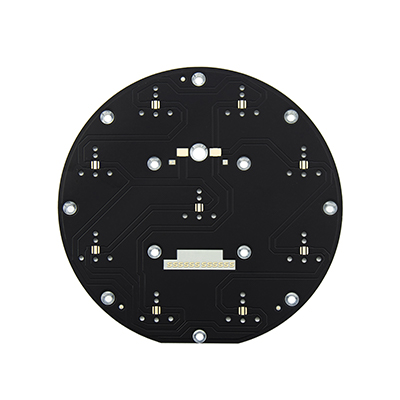

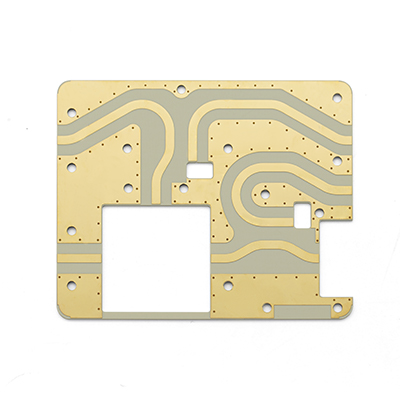

PCB Assembly

Sunking is your ideal partner for high-quality, medium and high volume electronic manufacturing, We offer a number of services including traditional PCB assembly and Surface Mount (SMT) assembly. and PCB finishing processes including conformal coating and silicone potting. We can also provide supply chain management, procurement, custom packaging and much more. We also develop test equipment including in-circuit testing and functional testing for all our products.

Our Services

High-quality SMT & THT production

OEM & ODM

Procuring components (BoM management)

Selective coating and varnishing, potting technology

Laser marking, DMX-Code, labels

Sample production & complex testing to support the development cycle

PCBA burning program

ICT & FCT & Aging test

Packaging concepts & design

100% optical and functional testing

PCBA Capability

Min.Assembly Space: 0.1mm

Min.QFP Space: 0.3mm

Min. Package: ‘0201

Min. Board Size: 50*50mm

Max. Board Size: 350*1200mm

Assembly Registration: ±0.01mm

Assembly Sort: QFP,QFN,SOP,PGA,PLCC,BGA…

Assembly Capability: 1206,0805,0603,0304,0204,0201…

Quality assurance

We maintain the highest standards of quality throughout the assembly process. All circuit board assemblies are barcoded and tracked through the various manufacturing steps. Our team analyzes the data collected at each stage during production to continually enhance and improve the process.

PCB inspection

A rigorous first article inspection process is performed on each build, complemented by a robust NPI procedure for new products. We produce build documents and machine programs from your information, as well as make recommendations for your designs to streamline your products’ manufacturing process.

Our series of inspections during the PCB assembly process are designed to ensure product quality, reliability and functionality, and to reduce field failures.

Equipment Specification

| Machine | Solder Paste Printer | SPI | SMT | SMT | SMT |

|---|---|---|---|---|---|

| Picture |  |  |  |  |  |

| Model | DSP-1008 | I350a | YS24 | YG12F | YG12 |

| Brand | DESEN | Sinic-Tek | YAMAHA | YAMAHA | YAMAHA |

| Board size | 50*50-400*340mm | 50*50-400*350mm | 0402~32*32mm L50*W50~L700*W 460mm | 0402~-45*100mm L50*W50mm-L510*W460mm | L50*W50mm~L510*W 460mm |

| Electrical source | 220V AC | 220V AC/15A | 220V AC | 220V AC | 220V AC |

| Power consumption(kw) | 3 | 1.6 | 4.7 | 4.7 | 4.7 |

| Air(kg/cm2) | 4.5~6kg/cm2 | 0.5Mpa | 0.45Mpa | 0.55Mpa | 0.55Mpa |

| Characteristics | Printing precision ±0.025mm Repeat accuracy ±0.01mm | Minimum pad spacing | SMT precision ±0.05mm( μ+3σ)、±0.03mm(3σ)Types of components120/8mm | Types of components 48/8mm | Types of components 60/8mm |

| Machine | Reflow | Reflow | Reflow | AOI | X-Ray |

|---|---|---|---|---|---|

| Picture |  |  |  |  |  |

| Model | Heller 1809 | Heller 1826 | FLEX XPM-2 | MT-2000 | ZM-X7800 |

| Brand | Heller | Heller | Vitronics | MVTE | SEAMARK |

| Board size | 50-508mm | 50-560mm | 50-560mm | 25*25~368*488mm | 500mm*500mm |

| Electrical source | 380V100 Amp/12KVA | 380V 3Phase | 380V | 220V | AC110-220V VAC50/60Hz |

| Power consumption(kw) | 43 | 43 | 12 | 4 | 1.7 |

| Air(kg/cm2) | 3 | 3 | 3 | 3 | 1.8 |

| Characteristics | Resolution:12μm FOV:20*20mm |