HDI PCBs

Your trusted HDI PCB manufacturer: Quick turn HDI PCB fabrication and manufacturing services in China

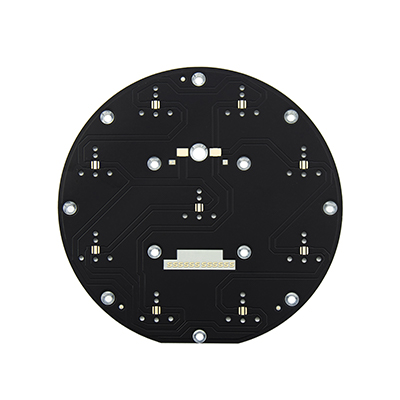

Quality HDI PCB Fabrication Services from SUNKING

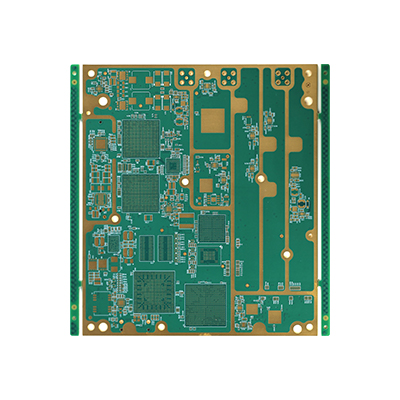

PCBs are not fabricated equally. HDI PCBs, for example, require close attention, expertise, and state-of-the-art equipment to manufacture. With the wide range of PCB fabrication choices, it is challenging to find a reliable and low-cost PCB service provider who offers quality HDI PCB fabrication services.

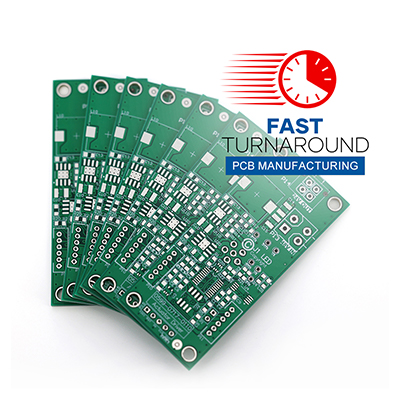

SUNKINGis trusted by some of the world’s major brands with the most demanding PCB industry requirements. In our 10+ years of PCB manufacturing, we have developed a good reputation as a high-quality and low-cost PCB service provider, including HDI PCBs. Besides, we are committed to expanding our capacities to meet our clients’ most demanding requirements.

Our state-of-the-art facility is located in Shenzhen, China. As the leading HDI PCB service provider, we continue to invest in cutting-edge fabrication and testing equipment. At SUNKING, we have a rich engineering background to handle complex PCB projects with unbelievable accuracy – quick turnaround times and on budget.

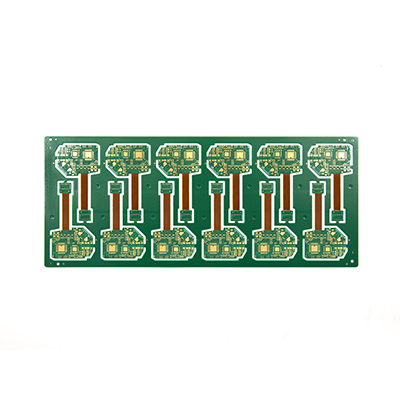

HDI PCB Structures We Support

We have the capacity to fabricate up to 30 layers of HDI PCB. Therefore, it all depends on your requirements. The table below shows the types of HDI structures we fabricate.

The Benefits of Using HDI PCBs

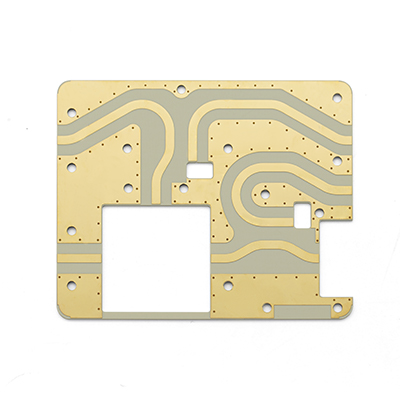

The Difference Between Standard and HDI PCBs

Standards printed circuit boards use through-holes to achieve high stray capacitance and a colossal discontinuity in impedance. In a layman’s language, they boost an average signal integrity performance. On the other hand, HDI boards use buried and blind vias to reduce the stray inductance and capacitances. The outcome is a strong signal integrity performance.

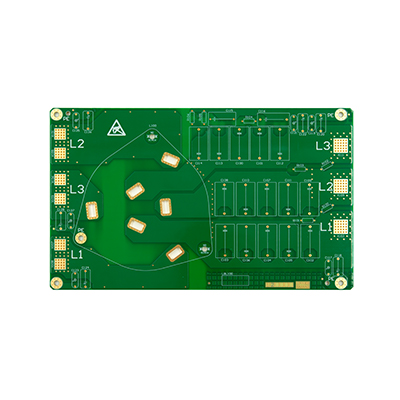

HDI PCB Applications

High-Density Interconnector PCBs are applicable in various industries. As mentioned earlier, you will find them in all sorts of electronic gadgets, where miniaturization plays an essential role in the effective use of the product. HDI PCBs are also common in automobiles, aircraft, and other vehicles that heavily depend on electronics.

One of the major industries where HDI boards are making massive exploits is the healthcare field. Medical equipment often requires small packages with super transmission rates, which only HDI boards offer. For instance, an implant should be small enough to fit in a human body, but all the equipment used in an implant must have high signal transmission capacities. In this case, the High-Density Interconnector boards make a good use case. These PCBs are also applied in other medical tools such as emergency room monitors, CT scans, and others.

No matter the industry you work in, HDI PCBs have the potential to enhance the electronics you deal with. Get in touch with us to discuss your requirements. We will advise you whether you are on the right track and help you exploit the benefits of HDI technology in your area of specialization.