IMS & Ceramics PCBs

High-quality and low-cost Aluminum PCB manufacturing services, a one-stop solution for all your Aluminum PCB needs

The Leading Metal Core PCB Manufacturer

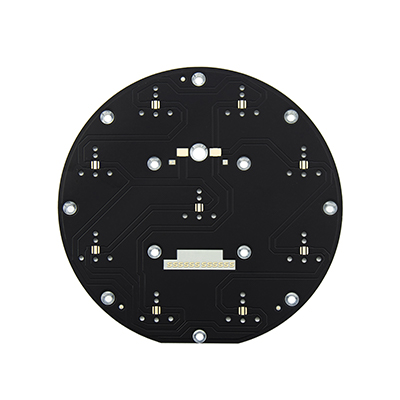

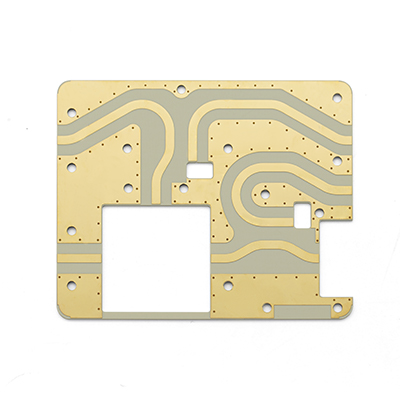

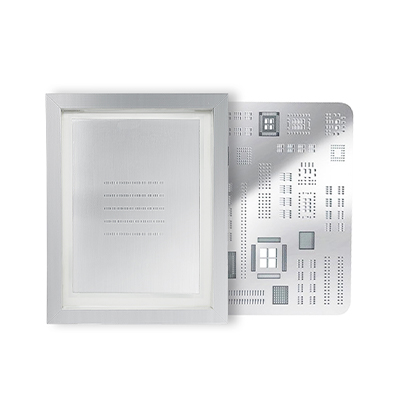

Among the metal core printed circuit boards, known for their capacity to offer high thermal dissipation, Aluminum PCB is the most common type. Generally, its base material is made of an aluminum core with standard FR4 materials. It contains a thermal clad layer that dissipates heat efficiently, cooling PCB components and enhancing their overall performance. Currently, engineers mostly recommend Aluminum PCBs for high-power and tight tolerance applications.

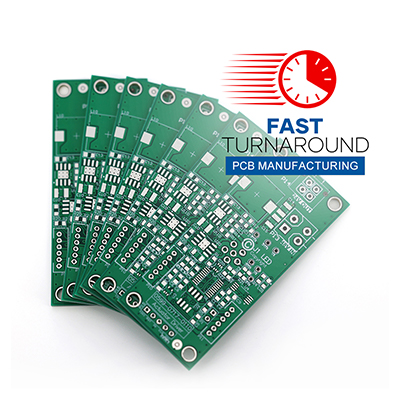

SUNKING has been fabricating aluminum circuits for more than ten years. Our full-featured metal core PCB manufacturing capacity and a thorough quality inspection process enable our customers to obtain high-quality products at competitive market prices. Our Aluminum PCB products are mainly used for LED lighting, power equipment, and automotive systems.

Benefits of Aluminum PCBs

Aluminum PCBs present several advantages such as:

Applications of Aluminum Circuit Boards

Typically, Aluminum PCBs are used in high-thermal dissipation applications: Aluminum can conduct the heat away effectively, eliminating the need for heat sinks. This makes Aluminum a low-cost and reliable option for managing PCB heat. Aluminum boards use dielectric materials to dissipate heat away from the source quickly. Hence, the heat-emitting components do not experience high thermal stress.

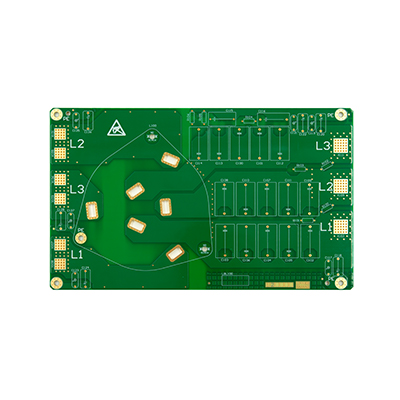

LED lighting: Aluminum PCBs are commonly used in LED lights, lamps, tube lights, and car lights. LEDs emit too much heat, and they cannot function normally without metal core PCBs with high thermal dissipation capacity.

Power supply: You can use Aluminum circuits to make DC/DC and DC/AC converters. In addition, you can also use them in automotive, telecommunication, computers, power modules, and other industries.

Applications of Aluminum Circuit Boards

Typically, Aluminum PCBs are used in high-thermal dissipation applications: Aluminum can conduct the heat away effectively, eliminating the need for heat sinks. This makes Aluminum a low-cost and reliable option for managing PCB heat. Aluminum boards use dielectric materials to dissipate heat away from the source quickly. Hence, the heat-emitting components do not experience high thermal stress.

LED lighting: Aluminum PCBs are commonly used in LED lights, lamps, tube lights, and car lights. LEDs emit too much heat, and they cannot function normally without metal core PCBs with high thermal dissipation capacity.

Power supply: You can use Aluminum circuits to make DC/DC and DC/AC converters. In addition, you can also use them in automotive, telecommunication, computers, power modules, and other industries.