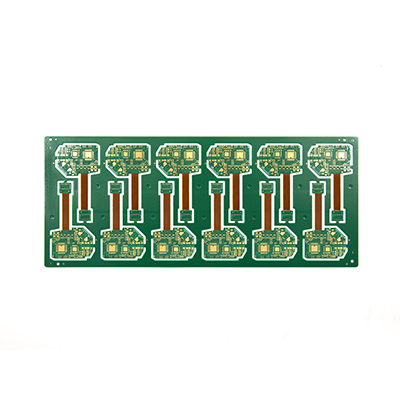

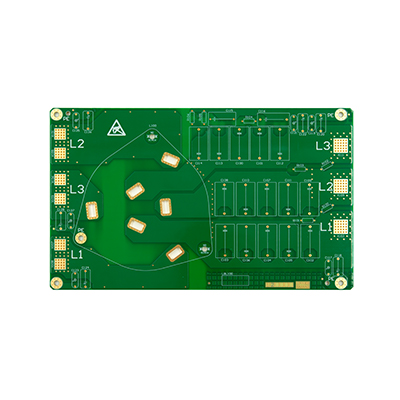

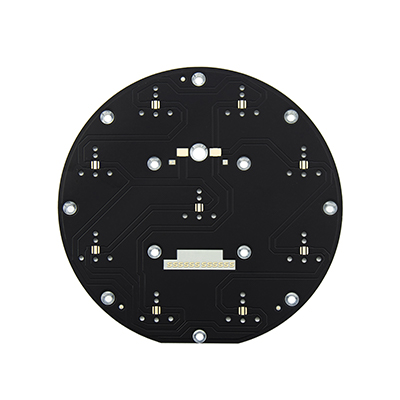

Flex & Rigid-Flex PCBs

Full Feature Flexible PCB Manufacturer

Types of Flexible PCBs We Offer

IPC Type 1:

These are single-sided flexible PCBs with one conductive layer. They are the most typical flexible boards, suitable for dynamic, flexible uses. IPC Type 1 flex boards come with or without stiffeners.

IPC Type 2:

These are double-sided flexible boards and have two conductive layers with PTH. They also come with or without stiffeners. Copper is attached on both sides of the base material, then drilled, etched, and insulated on the two sides with an upper and lower dielectric cover layer.

IPC Type 3:

These are multi-layer flexible PCBs and have three or more conductive layers with PTH. The PTH technique is applied to facilitate the interconnection of conductive layers. IPC Type 3 flex circuits come with or without stiffeners.

IPC Type 4:

They use multi-layer rigid and flexible boards having three or more conductive layers with PTH.

IPC Type 5:

These are flexible or rigid-flex PCBs. They have two or more conductive layers and lack PTH.

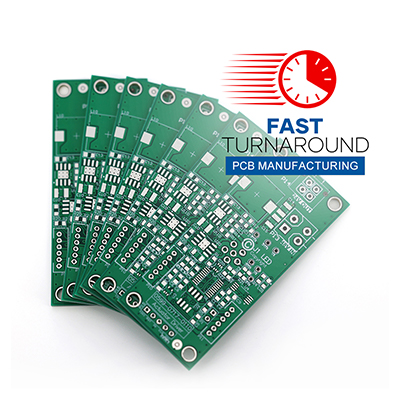

What Makes SUNKING Flex PCBs and Processes Unique

- MKTPCB is an experienced and reliable flexible PCB manufacturer. What sets us apart from other flex PCB manufacturers? First, we act as a single point of contact throughout the process of quoting, designing, production, and shipping. Secondly our flex PCB products come with multiple major differentiators that make them ideal for numerous applications.

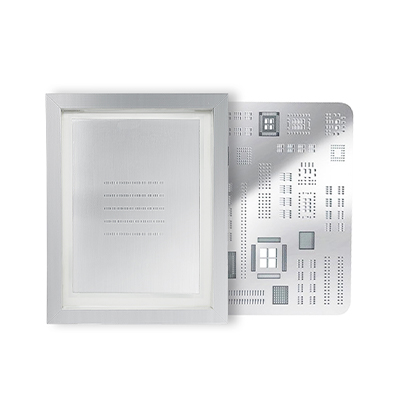

- We manufacture only the best-quality circuits using polyimide and thin copper foils on trace and space as 50 microns. We have refined our flex PCB production process for more than ten years to act as a one-stop-shop that meets all your PCB requirements.

- Our flexible PCB products have already proven themselves in various applications and sectors. Our products have been applied in handheld and implantable healthcare equipment. Besides, they have also been widely used in aerospace and automotive applications or consumer electronics like personal computers.

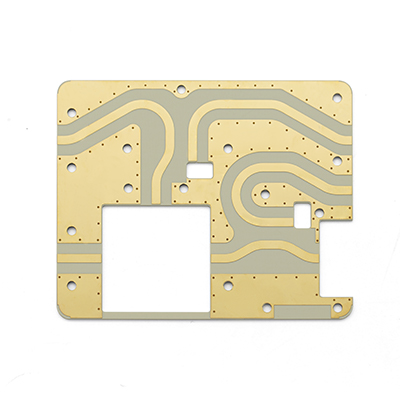

- Other than flexible circuits, we also fabricate rigid-flex printed circuit boards and HDI flex boards. Rigid-flex boards link conventional and flexible designs and are primarily used to connect multiple rigid-flex PCBs using flexible circuits.