High-Frequency PCB Manufacturing

High-quality and quick-turn high-frequency PCBs at competitive market prices

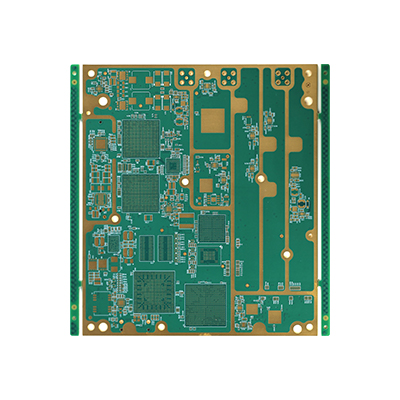

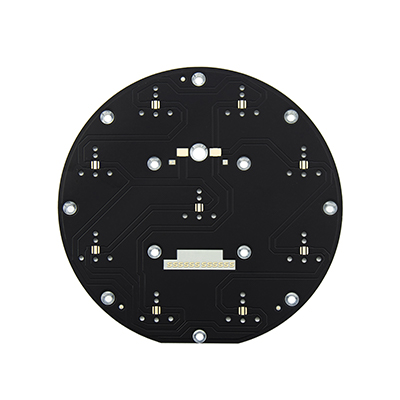

High-Frequency PCB Fabrication

A high-frequency PCB is suitable when integrating a particular signal with an electronic product. It boasts a frequency range of 500MHZ to 2GHZ, making it ideal for high-speed designs, radio frequency, microwave, and mobile applications. These higher transmission frequencies also offer faster signal flow rates essential in today’s increasingly complex electronic switches and components.

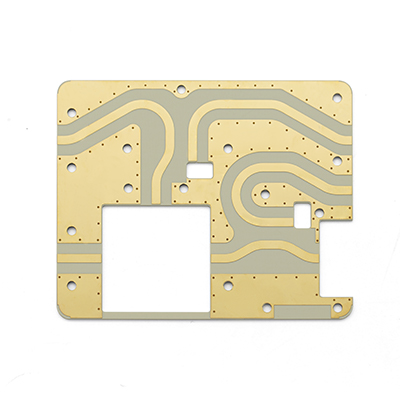

A high-frequency board requires specialized materials to establish high-frequency signals. Any slight change in the Er value of the materials will affect the PCB impedance. Most PCB manufacturers use Rogers dielectric material because of its lower dielectric loss, minimal signal loss, cost-effective circuit fabrication, and excellent appropriateness for quick-turn prototyping applications.

Besides selecting the suitable board material and determining the appropriate Er value, manufacturers also consider aspects like conductor width and spacing and substrate constant. These aspects should be precisely specified and executed with the highest process control level.

Why You Should Choose High-Frequency Circuits

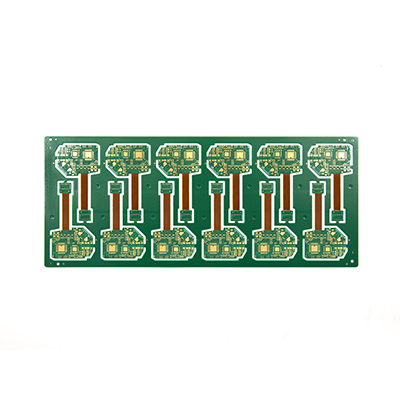

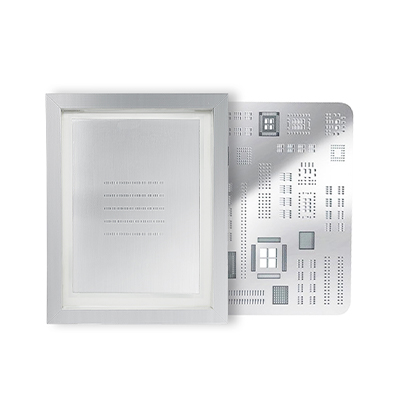

If your application requires a high-frequency board, you need a PCB manufacturer with extensive knowledge and rich fabrication background. High-frequency boards are challenging to produce since they should maintain the thermal heat conduction of the application. This calls for an experienced manufacturer who understands this property and pays close attention to the PCB base material since even a slight modification can affect the PCB impedance.Some of the factors that we pay close attention to when fabricating high-frequency circuits include selecting the appropriate material, heat sinking capacity, signal loss tolerance, working temperature, and production cost.Most PCB manufacturers cannot handle the above aspects. By emphasizing features such as the thermal expansion coefficient, dielectric constant, dissipation factor, and thermal coefficient, we can manufacture high-frequency products that meet your custom requirements.

Our High-Frequency PCB Manufacturing Capacity

The table below shows our high-frequency PCB manufacturing capacities

The Benefits of High-Frequency PCBs

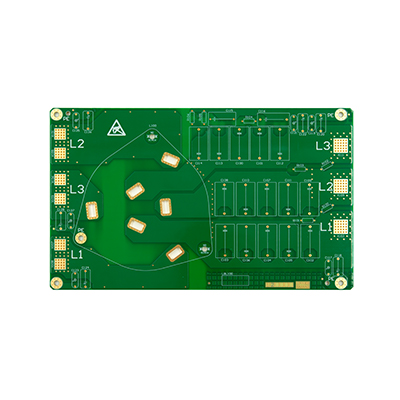

Application of High-Frequency Boards

Medical Applications

Like X-ray equipment, Heart rate monitors, MRI scanners, blood glucose monitors, etc.Electronic Communication

Mobile communication gadgets, receivers, and intelligent lighting system.Security and Safety

Radar systems, marine and aviation industries.Audio Industry

Power amplifier, low noise amplifier, and others.Industrial Applications

Power divider, coupler, duplexer, filter, and other passive components.Automotive Applications

In automobile anti-collision systems, satellite systems, and radio systems, the high frequency of electronic equipment is the development trend.